There is no stress on any of the wiring. The top strap also stops extreme angle of the headstrap. It works exactly the same as the vive deluxe strap.

If you dont have the 8K X yet, thats why you’re saying that. To change the angle with a dremel, you dont actually cut the hinge, you would have to cut the opening in the strap that takes the hinge inside it, to bore out the bump stops. If you make the wrong cut, it’ll fracture it and your strap will be worthless too, because the strap has plastic on the sides.

Only the hinge itself is metallic, and you can use a dremel possibly on the hinges inner prong to thin it more (possibly) but again, that prong is so small that it could backfire.

It’s possible, but i opted not to shave it down, because i’d rather have a strap that fits bad, than no strap at all because i broke it.

The 3d printed hinges work just as they do with the Vive DAS that i’ve used for a very long time. The headphone wires have enough slack to rotate the headset on the 8k x SMAS to do that.

By the way, hammerhead posted earlier that he will send out the plastic hinges to anyone that asks. He made a separate posting about it - just give him your order num

I dont get why pimax reps keep changing the title and taking the words “ergonomically horrible” out of it.

This should be an open forum to discuss opinions and find solutions, etc. By 2 different reps changing the title MULTIPLE times now, only makes me see more and more how Pimax is trying to control the narrative in the forums here.

What printer do you guys have. and what’s is the speed 200 mm/s ? or higher?

@MikeJeffries you too

I just picked up a FLSun QQ Delta and am unpacking it right now

(No i did not buy it specifically for this , that would be crazy  )

)

Lol. I use a Prusa Mini. New to 3d printing personally but have been slowly getting the hang of it. I really need to learn CAD more than anything. Im not sure about the speed. On Prusa’s printers it goes by a percentage in the Prusa Slicer app. I dont push it past 100% usually. Only on prints i dont care as much about I may go up to 110% or so.

I am a pretty much a master of sketchup which is good enough for now, but I would like to try that OnShape thing mentioned by @BNP

too bad they want your phone number to call you

Designing your own stuff is next level.

I have an idea to create a hinge that would allow us to set the HMD at different distances to help, instead of relying on different foam sizes.

What do you guys think is something like that possible?

basically the clip would be two parts that slide into each other at different levels. you would only need like 5 mm of adjustment

obviously this means that you would have to have a very squishy face foam that could expand to fill the gap.

To be honest i can tighten the strap alot more to fill the gap if needed. That means you plan on using a thick foam and want to adjust distance using the hinge from what i understand. But the strap can already be pushed in with the knob in the back. Not sure that the hinge also need to pull in/outwards also but sure put the design out there. You never know

yeah i’m thinking something more akin to the OG Vive’s adjustability in and out

if we could move it in and out it will solve a lot of peoples problems with getting the distance “just right”

plus i don’t like making the HMD too tight on my head.

Im thinking with a few notches even if it was just a couple 3 mm apart it would do the trick

if i was really advanced you could print a turnable knob that would lift the latch up while turning and it pull the device forward like a gear mechanism and then it would fall into the notch

do you know what im saying?

EDIT. my awesome freehand CAD skillz

ender 3

you would want to make a replacement / modification cowl if you want to adjust eye lens distance. unless you just wand to squish your face into foam which is not very comfortable in the length i imagne

i was not the one that mentioned oneshape, i think that is @Teigue. I’m using fusion 360.

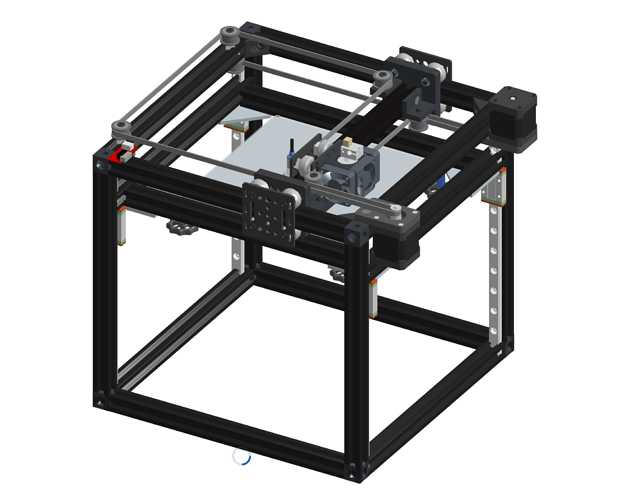

I have a custom built by myself coreXY printer, designed myself as well based on some existing designs & built from parts from lot of different aliexpress shops.

32 bit smoothieboard with compiled marlin + 1800 steps XY motors & 900 steps 2 Z motors

It can print much faster than 200mm/s but extruder doesn’t cope with speed on thick layers (only thin ones) + it can be a problem on such speed with different object shapes where plastic doesn’t cool enough & it leads to warping + some other issue like steps missing if it will create a blob & a carriage will bump into it on such a big speed so it won’t have a chance to melt it properly.

But some simple geometric object can be easily print at 200+mm speed on 0.2mm layer height

and I have solid state relay for heated bed & 24V PSU which helps a lot with acceleration, hold torque & temperatures times.

This all stuff is controlled by raspberry pi 3b+ model with octoprint system installed through exposed web/mobile interface, really handy

This is really old video https://www.youtube.com/watch?v=gNZ3lnUmOg0&t=51s

I had prusa i3 but had some issues with it, it was ok for first 3d printer but I wanted more fast system that time so I printed initially all parts in abs & continiously was modding this printer & still doing it from time to time if I have mood lol

very cool, hope you’re using it for more than just printing benchies

last year I mostly modding my HMDs & some useful tools like charging stations, cases for electronics etc & for sure printer mods as well, sometime something for vehicles (like mounting stuff etc). It’s handy in daily use to have a printer. Also lenses adapters are great.

Btw I never printed even a single benchy, just saw a lot on youtube haha

I’d only use the Dremel on the metal, not the plastic. I’ll reserve judgement until I get my 8KX. I might not even need to make any changes. I’d only mod it if I need to. And if I screw up, (as you said) I can always ask for the plastic hinge as a replacement. Another option is a friend who has a 3D printer, which can use any type of filament, including high-temperature ones, like nylon.

By the way, Hammerhead is a “she”, not a “he”. ![]()

Theres the post in case anyone didnt see it about replacing your hinges for the plastic ones that they had originally. It’s also now notated in the weekly update. Even the pics from hammerhead show how high the angle is with the metal hinges.

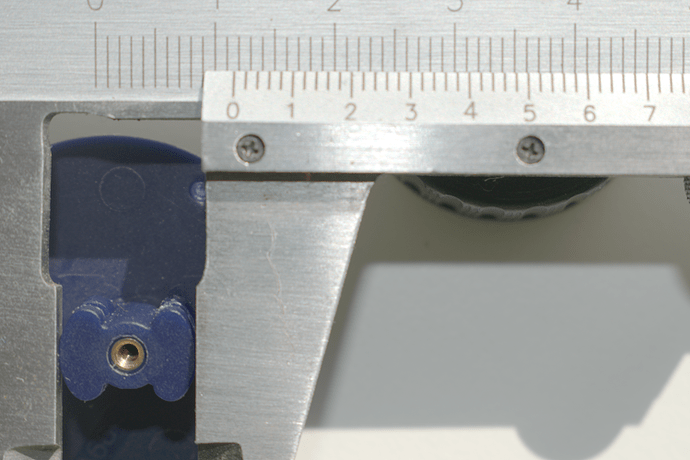

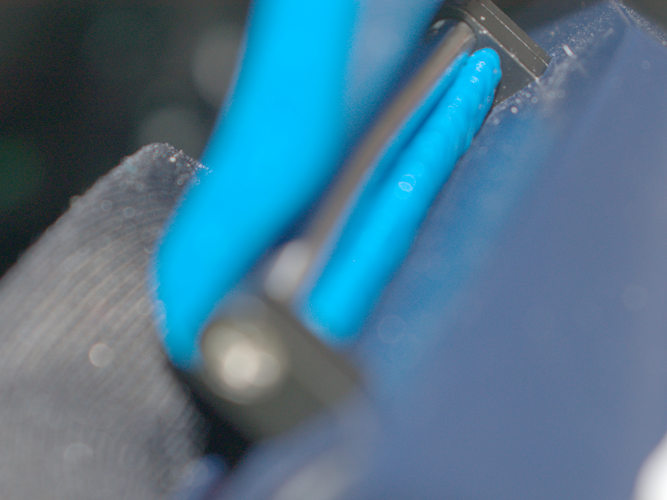

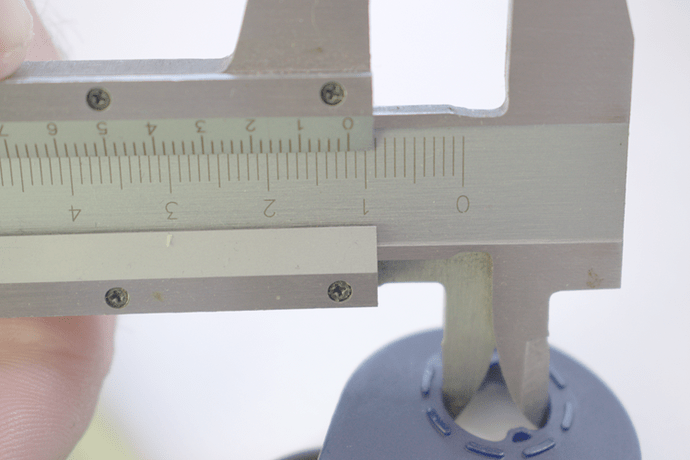

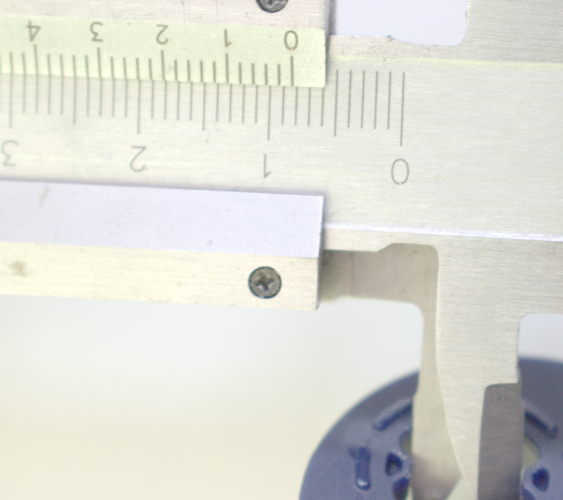

@Teigue just got time to print your hinges from thingiverse tonight. at 100% they’re definitely too big, mostly a problem around the hinge side where the material is too thick to fit around the metal rod and prong part which is a bit too big. I’ll try to get some pictures tomorrow.

but you printed the plastic variant right?

i dropped all 4 files on the buildplate, so yeas… probably

Also on thingiverse there is video which describes how to change the angle & diameter of the prong, if you don’t mind please try to adjust it according your plastic strap variant & tell the number or at least point exactly where the problem & how much it should be changed, coz it’s a bit not clear for me, I assume it couldn’t pass through the hole in SMAS strap right? where 2 protrusions are.

Or you can fit it inside but the default cap can’t be secured? Or prong is too thick & strap can’t rotate again the hing prong axis

around the hinge side where the material is too thick to fit around the metal rod and prong part which is a bit too big. I’ll try to get some pictures tomorrow.

Sorry ignore my above message, seems I got you, so the metal rod is the HMD flap connector which we used to detach & attach hingres to, so I assume the “hook” of the hinge which connect to the HMD is a bit thick & Mike didn’t test it as well.

Just let me know how much, can you use your knife & try to fit those though, just want to know how the comfort is with modified hinges